Create a free profile to get unlimited access to exclusive videos, sweepstakes, and more!

X-rays probe food at a molecular level to make future snacks even more tasty

We want Brussels sprouts that taste like chocolate, please and thank you.

How do you imagine the perfect snack food? Is it salty or sweet? Crunchy or chewy? Is it empty calories or does it fill you with a sense of satisfaction unlike any other? Those are the questions scientists at the University of Copenhagen are trying to answer using Small Angle X-Ray Scattering (SAXS).

Lilia Ahrné is a professor in the university’s Department of Food Science and is using the technology, along with her colleague Jacob Judas Kain Kirkensgaard, to probe the nanoscale structure of foods to find out what makes them tick.

“We’re interested in better understanding the structure of foods, particularly plant-based foods. This technique is interesting because you get better information about the structure of food which is strongly related with texture properties,” Ahrné told SYFY WIRE.

The popularity of plant-based foods has grown increasingly over recent years, with vegan and vegetarian meats, eggs, and dairy growing at twice the rate over overall food sales. Much of the recent success of plant-based meats can be laid at the feet of new products like Beyond and Impossible burgers which more closely resemble the real thing in taste and texture.

Ahrné hopes that by better understanding the internal structures of foods we might be able to construct more convincing plant-based alternatives, capture more of the food market, and reduce the negative impact of meat production on the climate. The sensory experience of eating a food is only the first part of the problem, however, capturing nanoscale structures can also tell us about how foods are broken down in the body.

“We want to know how structures can be created, but also how they’re destroyed. Biting and cutting into small pieces, the whole enzymatic processing. That part is pretty important for absorption and nutritional value,” Ahrné said.

For now, the team has been studying milk, which has an interesting internal structure. Dairy milk is a complex colloidal system which remains stable over time. A jug of milk left in the fridge for days will maintain its internal structure. It’s the same a week later as the day you bring it home. Plant milks, by contrast, are also colloidal but unstable. They settle and need to be shaken to redistribute their components.

“If you want to achieve a product that’s a stable colloidal system, it’s difficult,” Ahrné said. “We know that milk does it and that information can be used to create better plant-based milks. Milk also has calcium in a super saturated condition. It’s a fantastic delivery system. Learning how calcium is organized at the structural level could make that possible with plants.”

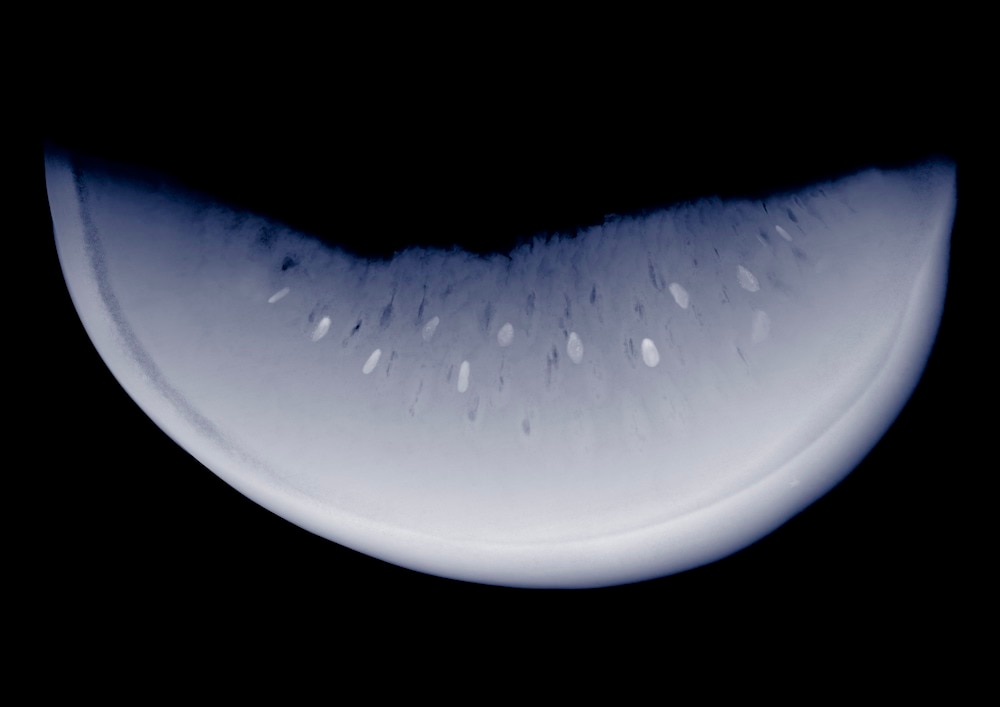

SAXS works by bombarding a sample with X-rays inside the sample loader. Most of the X-ray radiation passes through the sample but some of it will hit internal molecules and scatter. The pattern of scattering is collected on the other side by a sensor and that data can be used to reconstruct the shapes of molecules inside the sample. This allows scientists to gain data about the internal composition of foods and liquids and incredibly small scales, down to the nanometer.

“The advantage of this technique is that you can look at structures at the nanomolecular level and extract information that otherwise is not possible,” Ahrné said.

The SAXS machine at the University of Copenhagen has a simple user interface and is available for student use. The team hopes that by making this technology more widely available, we might be able to uncover new innovations in food science.

By building maps of the structures nature has created, food scientists and companies can recreate them in a laboratory or factory setting to craft foods which taste better, are more nutritious, and have a smaller impact on the environment.

There’s work to be done, but if things go according to plan, the future of foods might truly be guilt free.