Create a free profile to get unlimited access to exclusive videos, sweepstakes, and more!

Is this how Transformers began? MIT scientists roll out new micro-unit building blocks

Transformable sentient machines seen in the Transformers franchise are still a long ways off, but there must have been one pivotal moment when a key piece of technology was developed to act as a cornerstone for future development in that fictional world. This might be one of those inventions!

Scientists at MIT's Center for Bits and Atoms have designed an assortment of miniature polymer building blocks that demonstrate a number of highly unique mechanical properties, like the power to exhibit twisting motions when squeezed. Subunits could be combined and assembled by robotic equipment into an infinite variety of structures with integrated functionality, including cars, huge industrial parts, or specialized robots that can be repeatedly reassembled into different forms.

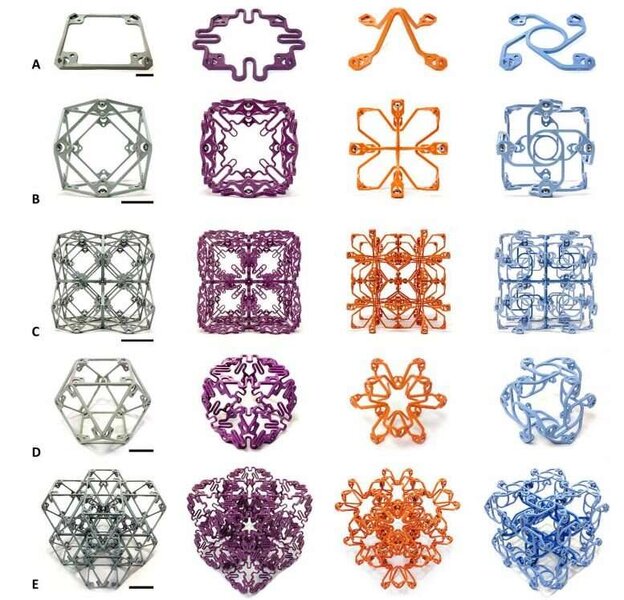

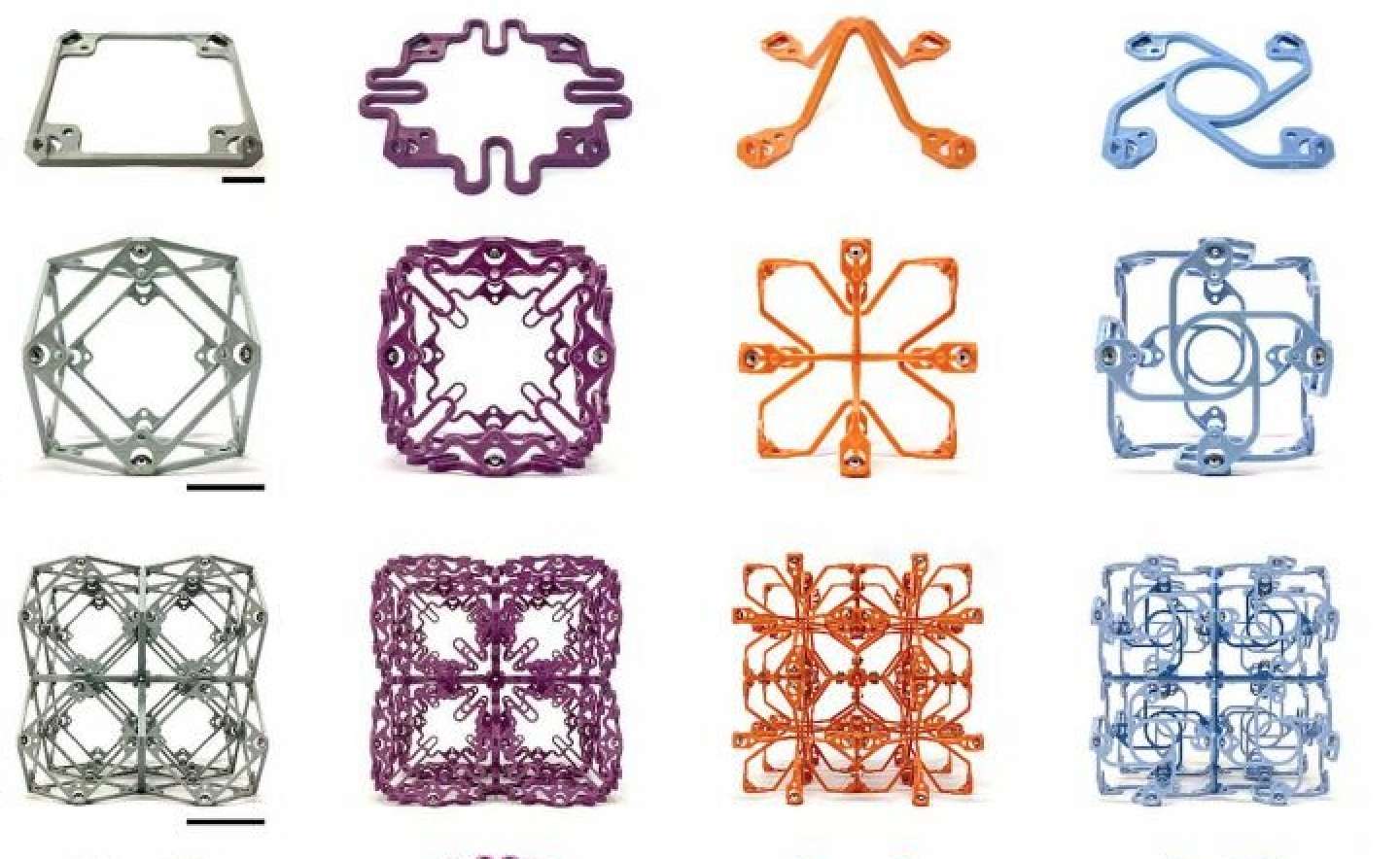

In findings published this week in the journal Science Advances, researchers created four different types of these mechanical metamaterial subunits, dubbed voxels, and named after their 3-D variation on 2-D image pixels.

Each specialized voxel model displays properties unseen in traditional natural materials, and employed in combinations, can be directed to produce devices which react to environmental stimuli. Such usages could include aircraft wings or turbine blades that are sensitive to air pressure changes or wind velocity by altering their overall shape.

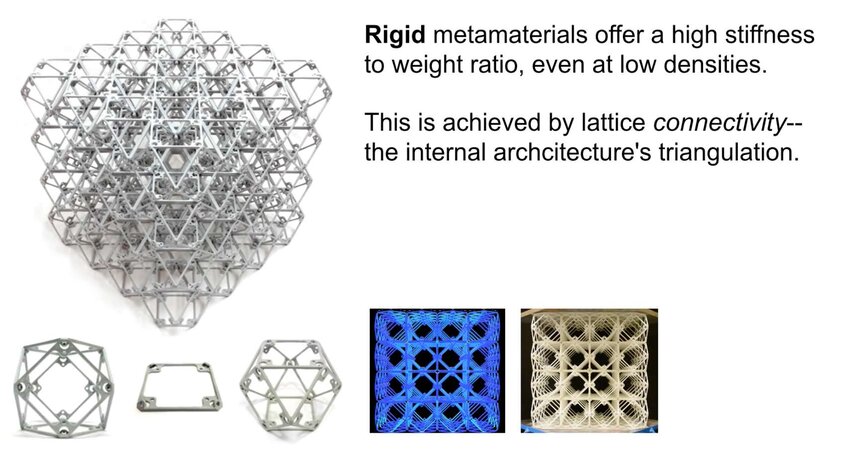

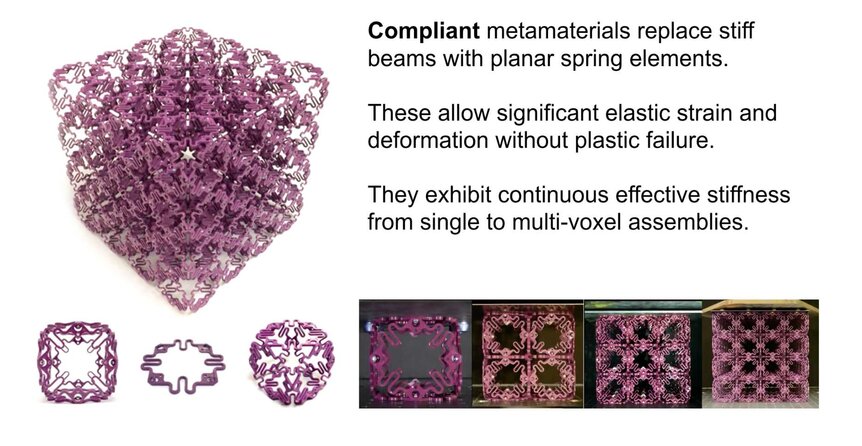

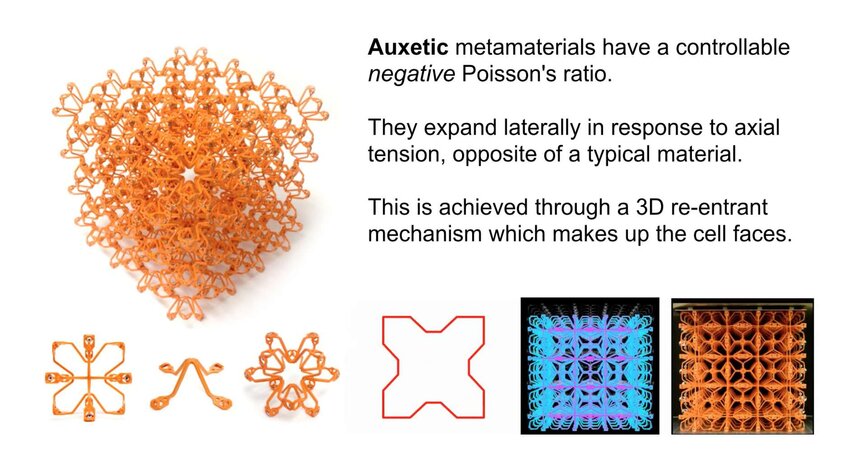

Acting like intricate LEGO building bricks, voxels are made from flat-frame pieces of injection-molded polymers, and then manufactured into three-dimensional shapes that can be combined into larger structures, providing a lightweight yet rigid framework when joined together. Besides the standard rigid unit, there are three other voxel iterations: rigid (grey), compliant (purple), auxetic (orange), and chiral (blue). Each one offers many unusual properties scientists were quick to note.

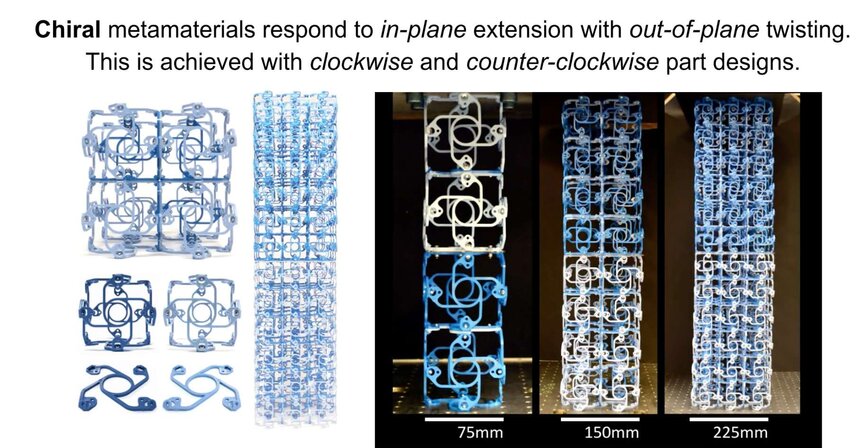

A cube of auxetic voxels bulge inwards at the sides when compressed instead of bulging outward. The sides of compliant voxels don't alter their shape at all when squeezed, which is an extreme rarity in materials science. Chiral voxels respond to axial compression or pulling with a strange twisting motion, another bizarre property almost never seen.

"Each type of material property we're showing has previously been its own field," says paper co-author Professor Neil Gershenfeld. "People would write papers on just that one property. This is the first thing that shows all of them in one single system. We can span a wide range of material properties that before now have been considered very specialized.

"The point is that you don't have to pick one property. You can make, for example, robots that bend in one direction and are stiff in another direction and move only in certain ways. And so, the big change over our earlier work is this ability to span multiple mechanical material properties, that before now have been considered in isolation. Think about all the rigid parts and moving parts in cars and robots and boats and planes. And we can span all of that with this one system."

According to lead study co-author, MIT doctoral graduate Dr. Benjamin Jenett, one notable benefit of the metamaterials system is that a complex structure composed of just one type of voxel acts exactly the same way as a single subunit.

"These parts are low-cost, easily produced, and very fast to assemble, and you get this range of properties all in one system," he explains. "They're all compatible with each other, so there's all these different types of exotic properties, but they all play well with each other in the same scalable, inexpensive system. We were able to demonstrate that the joints effectively disappear when you assemble the parts together. It behaves as a continuum, monolithic material."

Building blades for wind turbines at an operating site is a particularly desirable application of these variable voxels, which would eliminate the transportation element when the giant blades are shipped to their installations. Also, the environmental issue of turbine blade disposal might also be addressed due to blades being capable of disassembly back into the component voxels which could be recycled into other products and parts.

"Now we have this low-cost, scalable system, so we can design whatever we want to," Jenett adds. "We can do quadrupeds, we can do swimming robots, we can do flying robots. That flexibility is one of the key benefits of the system."