Create a free profile to get unlimited access to exclusive videos, sweepstakes, and more!

Astronauts aboard the ISS can breathe easy now that NASA has launched an upgraded CO2 eliminator

If there’s one thing you don’t want to breathe in space (besides potentially hazardous lunar dust), it’s carbon dioxide. That could be a problem when everyone around you is breathing it out.

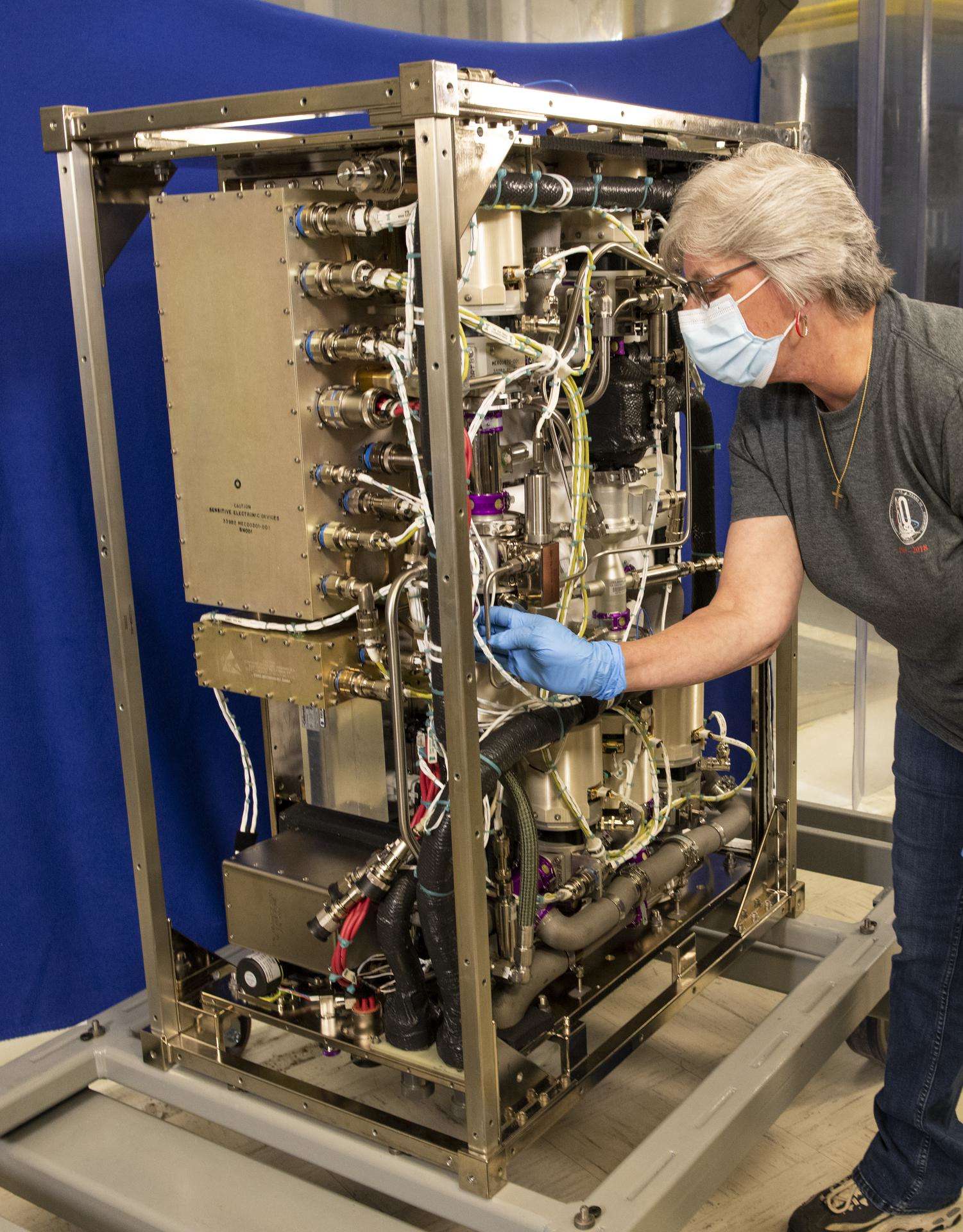

NASA has been upgrading the solution for that through several iterations of CO2 scrubbers that were tested on the ISS. These machines remove excess CO2 from the air and send it into the void. The space station’s Carbon Dioxide Removal Assembly (CDRA) is getting there, with its newest assembly just recently integrated, but there are still some issues. Enter the 4-Bed Carbon Dioxide Scrubber (4BCO2). This next-gen filtering tech is the life support system of the future.

The new scrubber recently blasted off to the ISS on Northrop Grumman commercial resupply mission NG-16 after extensive development, building and testing at NASA Marshall in Huntsville, Alabama, with collaboration from NASA Johnson in Houston. It was then sent into low-Earth orbit from NASA’s Wallops Island facility in Virginia (SYFY WIRE was there for that launch).

“Since 4BCO2 is an evolution of the existing ISS CO2 Removal Assembly (CDRA), we were able to identify the root causes that led to premature failure of CDRA components and/or drove maintenance of CDRA components,” scientist Michael Salopek of NASA Johnson told SYFY WIRE.

Carbon dioxide concentrations of more than 8 percent can be lethal to humans. If one broke down in the middle of a deep space mission, the outlook would be grim. Scrubbers require an adsorbent substance—porous material also called a molecular sieve—whose surface atoms or molecules will adhere to. This is why NASA is constantly leveling up ways of getting rid of the stuff astronauts exhale. Turned out that most of the degradation CDRA experienced was happening because the zeolite being used to grab CO2 molecules from the air left behind too much dust clogging up its filter.

Zeolites are mashups of mostly aluminum, silicon and oxygen that can purify the air. They act as molecular sieves because there is a limit on the size of molecules that can get past their pores. The types NASA has used do not let CO2 molecules in, so they remain stuck to the surface until being recycled to create water or released into space through a vent. Water vapor is also taken out of the atmosphere but returned to the cabin. What makes Salopek anxious to see results from 4BCO2 is the possibly of improving on current technology and get us one step closer to the Moon, and eventually Mars.

“Repeated testing led to a stronger zeolite bead being selected,” he said. “That way, environmental loads experienced by the beads were reduced, all with the goal of reducing the production of zeolite dust, which caused filters in the system to clog which reduced performance and caused the valves to wear out faster due to dust buildup.”

NASA Marshall scientists tested several types of zeolite before they found the right match. They were finally able to find one that stayed intact even after grueling tests meant to find out how much heat, pressure and loading it could take. The actual beds of adsorbent material were also redesigned to take more of a load off the zeolite. Valves in 4BCO2 are a redesign of the CSRA model that can withstand more dust, be easily maintained and give zeolite more time to adjust to being re-pressurized in the space station after being exposed to just about zero pressure while filtering CO2 out into the darkness.

4BCO2 is also equipped with a new blower that is the result of a NASA commercial partnership. This blower has magnetic bearings that hold out much longer than their mechanical counterparts, and will direct purified air through the beds of adsorbent zeolite and back into the cabin, giving astronauts a sigh of relief.

“The new valves were tested against the legacy valve design and did not experience higher torques or drive failures when exposed to a worst case life time of dust and cycles”, Salopek said. “Magnetic bearings could completely eliminate mechanical wear.”

Between this and the new space air conditioning system NASA is testing out, putting human footprints on the Moon again and Mars for the first time is becoming more and more of a reality.